3D printing for ecosystem restoration

At first glance, plastics and aquatic ecosystem restoration may seem like an unlikely combination. By now, most of us are familiar with the term “plastic soup.” However, biodegradable plastics could play a crucial role in restoring coastal ecosystems. In collaboration with NIOZ, Utrecht University, and Bureau Waardenburg, we are testing whether creating hard substrate structures can support the restoration of shellfish reefs and seagrass meadows.

Share this project

Improving Habitat for Bioengineers

The Wadden Sea and the Southern Delta are dynamic environments, constantly shaped by currents, waves, and storms. In such ever-changing conditions, it can be difficult for oyster larvae or seagrass seeds to settle and grow. Research has shown that providing suitable hard substrates can stimulate the settlement of shellfish larvae. Similarly, the survival rate of seagrass seedlings can be improved by stabilizing the seabed. Both oysters and seagrass are considered bioengineers, as they modify their surroundings in a way that creates ideal habitats for many other species.

3D Structures as a Catalyst for Reef Formation

In the Building with Bioengineers project, we experiment with biodegradable structures made from bioplastics and natural cement to serve as stabilizing substrates. Traditional materials like concrete remain in the environment for decades as man-made structures on the seabed. But what if we could use structures as a temporary boost to natural reef formation? Ideally, these materials would degrade naturally after fulfilling their restorative role, leaving behind only new, diverse marine habitats.

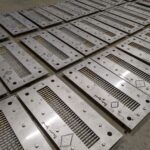

Once bioengineers establish themselves, they can expand their habitat independently. Our research focuses on designing optimal structures and identifying the most suitable biodegradable plastics. To rapidly prototype new designs, we use 3D printing technology for small-scale production. We are also developing our own natural cement. The knowledge gained from this research is not only applicable to marine ecosystem restoration but could also be useful for other soft-bottom environments, such as peatlands.

Field Experiments

The Fieldwork Company has previously studied the degradation rate of biopolymers like PBS and PLA in marine environments in the Wadden Sea and Grevelingen. Our findings showed that these biopolymers do not break down quickly enough in seawater and that structures can disintegrate too fast due to wave action.

In our ongoing research, we are testing the degradation of other biopolymers, such as PCL, PBSA, and PHA, in different environments. Besides material selection, we are also researching the ideal shape and structure of substrates. Previous experiments tested the optimal cavity size in 3D-printed pyramids for shellfish settlement.

In our latest study, we have combined our knowledge of biopolymers and natural cement to create a “reef nest.” These structures are designed to encourage shellfish to form new reefs. Additionally, we are identifying areas in the Wadden Sea suitable for the active or passive restoration of shellfish reefs and seagrass meadows.

By combining insights from all these studies, we aim to develop the most effective structures and find the best locations for bioengineer restoration. Want to learn more about the 3D printers we use for this research? Click here: 3D Printing.

Client

NIOZ

Contact

Location

Waddenzee, Grevelingen, Fochteloërveen, Groningen

Project status

In uitvoering

Involved part(ies)

Universiteit Utrecht

Bureau Waardenburg

Waddenfonds